BHIWADI JAL PRADUSHAN NIVARAN ASSOCIATION

Safeguarding Bhiwadi's Future: Clean Water, Sustainable Growth.

A Brief

CETP BHIWADI

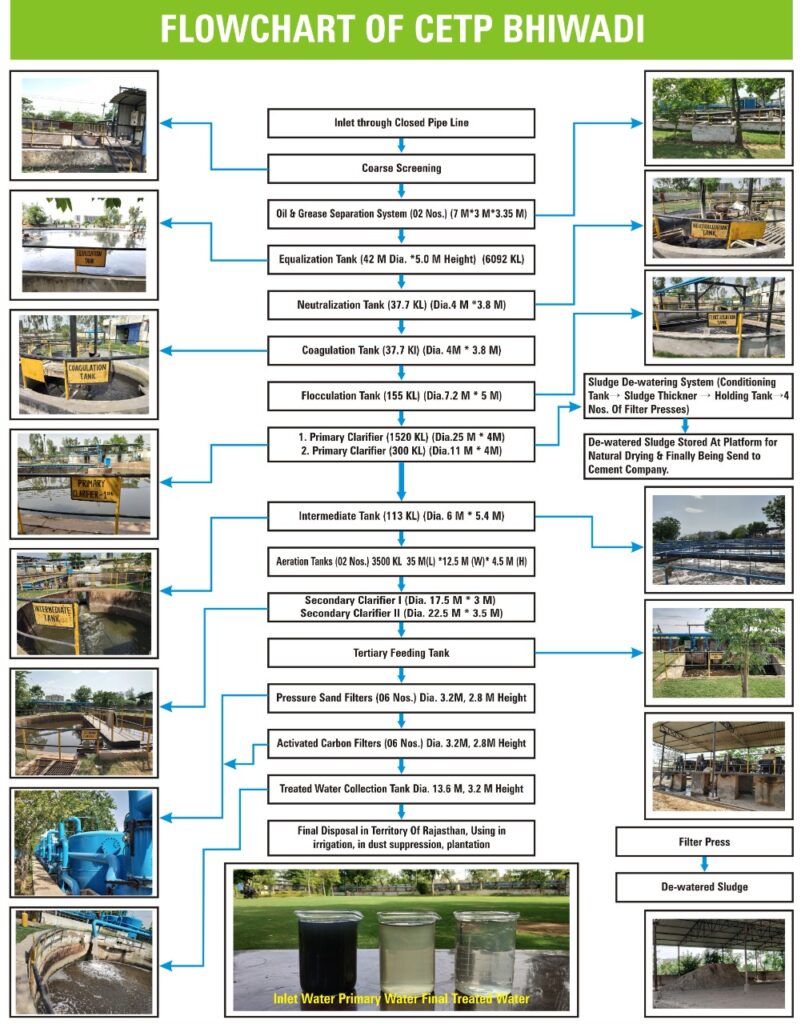

The Common Effluent Treatment Plant (CETP) in Bhiwadi, with a capacity of 9 MLD (Million Liters per Day) and a 100 KLD (Kilo Liters per Day) Spent Acid Neutralization Plant, is a critical piece of infrastructure that plays a crucial role in the sustainable development of the region. Rapid industrialization and the addition of domestic wastewater in Bhiwadi have led to a significant increase in the volume of wastewater discharged from the region, which can be hazardous to the environment if not properly treated.

A Brief

Spent Acid Neutralization Facility Flowchart

The spent acid neutralization facility at CETP Bhiwadi plays a vital role in mitigating the environmental impact of industrial activities by effectively neutralizing acidic effluents. Through a series of carefully orchestrated steps, the facility ensures that spent acid is safely treated and disposed of, contributing to a cleaner and healthier environment.

Why Choose Us

Safeguarding Bhiwadi's Future: Clean Water, Sustainable Growth.

Industry Leadership

With years of experience and expertise, CETP Bhiwadi stands as a beacon of excellence in wastewater management.

Innovation and Efficiency

Continuously striving for innovation, we invest in research and development to optimize our processes and minimize environmental impact.

Environmental Stewardship:

We prioritize environmental sustainability by adhering to strict treatment protocols and utilizing advanced technologies to ensure that discharged water meets regulatory standards.

At CETP Bhiwadi, we are committed to ensuring a cleaner, greener future for Bhiwadi and its surrounding regions. As a premier Common Effluent Treatment Plant (CETP), we play a pivotal role in managing industrial and domestic wastewater responsibly.

Efficient Wastewater Solutions Tailored for Bhiwadi's Manufacturing Units

- Primary Treatment: Removal of physical contaminants such as solids and oils through processes like screening and sedimentation.

- Secondary Treatment: Biological processes to break down organic pollutants, ensuring a higher level of water purification.

- Tertiary Treatment: Advanced processes like filtration and disinfection to further enhance water quality before discharge.

- Specialized facility equipped to neutralize acidic industrial effluents, preventing harmful environmental impact.

- Utilization of neutralizing agents to adjust pH levels and render spent acid safe for disposal.

- Tailored wastewater management solutions designed to address the specific requirements of each manufacturing unit.

- Flexible service options to accommodate varying production volumes and effluent characteristics.